### Blog Post:

widia cutting tools are essential in modern metalworking and manufacturing, offering reliability and cost-effective solutions for small and mid-scale operations. Whether you’re machining steel, alloys, or composites, understanding how these tools fit into today’s fast-growing market can save you time and money while boosting performance.

Key Takeaways

- Widia cutting tools are known for reliable, cost-effective performance, particularly for small and mid-scale machining operations.

- Carbide tools and inserts, including Widia’s, dominate the metal cutting tools market due to tool life and efficiency advantages.

- Understanding the market context and common pitfalls can help you maximize tool performance and ROI.

- 1. The Core Concept

- 2. Step-by-Step Guide

- 3. Advanced Analysis & Common Pitfalls

- 4. Conclusion

- 5. FAQ Section

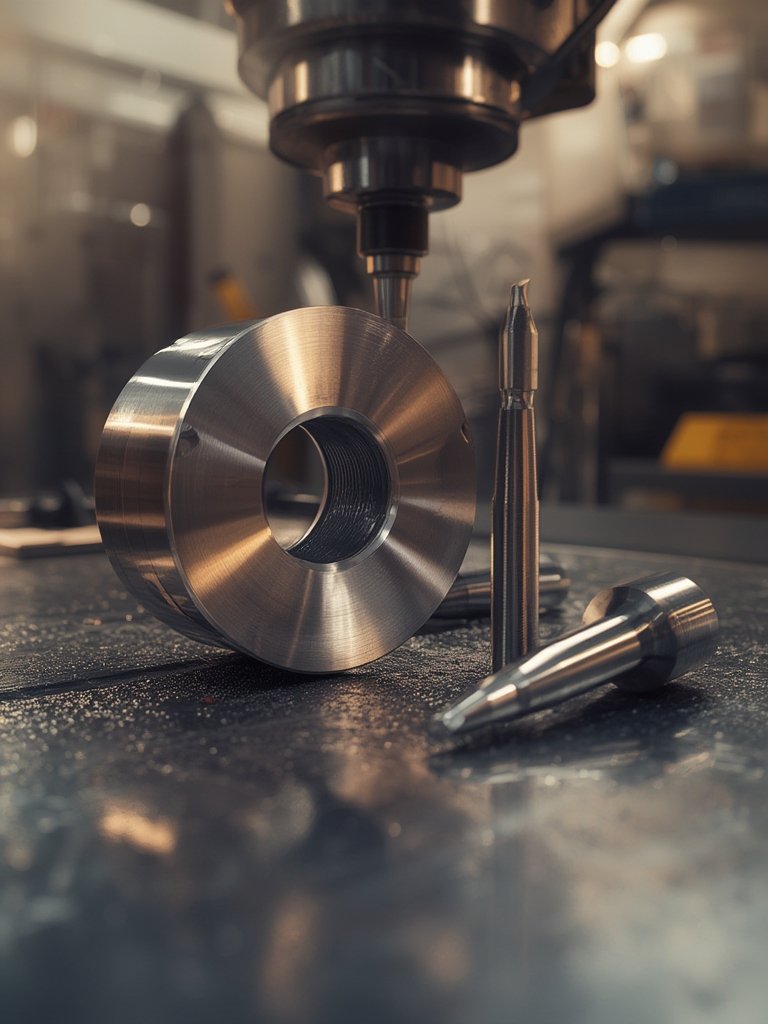

The Core Concept: What Are Widia Cutting Tools and Why Do They Matter?

Widia cutting tools are a mainstay in the metalworking industry, engineered to handle demanding applications in milling, turning, drilling, and grooving. These tools, often using carbide-based inserts, are favored for their durability, performance, and cost efficiency. The global market for cutting tools is rapidly expanding, projected to grow from USD 26.11 billion in 2025 to over USD 44.87 billion by 2033, indicating more manufacturers are relying on advanced solutions to meet increased production demands.

Why does this growth matter for users of widia cutting tools? Carbide inserts now account for more than 60% of indexable milling cutter usage, with modern coatings like coated carbide PVD and CVD extending tool life by up to 25%. This means lower costs per part and less downtime for tool changes. Widia, as referenced in the Future Market Insights indexable milling cutters report, continues to maintain a presence as a trusted, value-focused choice especially for small and midscale operators.

However, market research reveals that while Widia is well-positioned, it is often outpaced in awareness, technical documentation, and user testimonials by competitors with more aggressive marketing. Without public technical datasheets and head-to-head comparisons, many buyers rely on word of mouth and distributor advice—a double-edged sword that can make purchasing less precise.

For those who want actionable product recommendations beyond cutting tools, consider our roundup of top product picks and recommendations for home improvement.

Step-by-Step Guide: How to Select, Apply, and Maintain Widia Cutting Tools

Choosing and using widia cutting tools effectively requires a structured approach. Follow these steps to optimize performance and avoid common missteps:

- Define Your Machining Requirements: Understand the materials (e.g., mild steel, hardened alloys) and the type of operation (milling, turning, drilling, threading) you are running.

- Select the Correct Insert Geometry and Grade: Not all widia carbide inserts are equal. Confirm compatibility with your machine and the required application. Coated carbide (PVD, CVD) often gives better tool life—studies show a 14% annual adoption increase due to this.

- Source from Authorized Distributors: Purchase from trusted suppliers to avoid counterfeits, outdated grades, or subpar alternatives. Unfortunately, customer feedback and official specs are limited online, making reputable sourcing crucial.

- Install with Care: Ensure inserts are clamped securely, using torque settings as specified by your machine builder. Improper installation is a leading cause of insert failure.

- Optimize Cutting Parameters: Adjust speed, feed, and depth of cut based on the material, insert recommendation, and observed performance. Use modest starting parameters and scale up if chatter or excessive wear is not present.

- Monitor Tool Wear Trends: Track insert life with logs or counters. Replace inserts proactively; running dull tools can damage your workpiece or holder, leading to higher costs.

- Practice Regular Maintenance: Clean holders and turret pockets. Remove chip buildup and check for signs of slippage or cracking.

If you’re also considering other home workshop upgrades, see our guide to the best cordless drill for home use for tool setup efficiency.

Need an edge in keeping your workspace spotless from chips and debris? The self emptying robot vacuum for pet hair picks work great for machine shop floors too.

Advanced Analysis & Common Pitfalls

The boom in carbide cutting tools and indexable milling cutters reflects real-world gains—higher productivity, longer tool life, and lower per-part costs. Carbide leads thanks to a 63% market share in 2024, pushing the shift away from HSS and older solutions.

But there are clear challenges when working with widia cutting tools:

- Lack of Public Technical Data: Many potential buyers cannot access detailed Widia datasheets, application charts, or cutting parameter tables, making optimal selection more difficult.

- Variable Distributorship Knowledge: Since Widia’s market presence relies heavily on distributors, your experience may vary depending on local technical support or inventory depth.

- Confusing Insert Grade Naming: Some users report confusion due to limited online visibility into grade/purpose differences within the Widia line.

- Underutilization of Coated Inserts: With PVD/CVD coatings boosting tool life by up to 25%, not upgrading to coated inserts can leave savings on the table.

Here’s a side-by-side of advantages and downsides to consider:

| Feature | Widia Cutting Tools | Common Pitfalls |

| Cost Effectiveness | Generally lower price point for small/mid-scale needs | May lack premium features or latest grades found in flagship competitors |

| Availability | Wide distributor network for standard tooling | Special or custom inserts harder to source quickly |

| User Resources | Basic documentation available via distributors | Limited online support/community forums and application case studies |

| Tool Life | Solid with standard applications and coated grades | Bad parameter selection or use of uncoated tools can shorten lifespan |

If you’re interested in upgrading general workshop efficiency, our types of measuring tools guide can help you choose the right metrology tools to complement your cutting operation.

For sealing and assembly essentials, check the Seal Right tool kit for industry-standard sealing solutions.

And if you’re outfitting your production or storage area, mobile modular portable storage can protect both tools and raw stock.

Conclusion

Widia cutting tools are a dependable, budget-friendly choice for industrial machining in today’s fast-evolving manufacturing world. Although public resources for grade selection and reviews are limited, these tools remain a go-to for small and midsize shops needing reliable carbide inserts at scale.

By following a careful selection and maintenance process, and by staying aware of common pitfalls, you can maximize performance and lifespan from widia cutting tools. Ready to outfit your shop or upgrade your toolroom efficiency? Start evaluating your current needs and consider reaching out to an authorized distributor for the latest options and pricing.

FAQ Section

Are widia cutting tools compatible with all CNC machines?

Most widia cutting tools and inserts are designed to fit industry-standard tool holders and turrets. However, it’s important to double-check exact insert specifications and machine compatibility before purchasing.

How do coated widia carbide inserts improve tool life?

PVD and CVD coatings on carbide inserts reduce friction, heat, and wear, extending cutting edge life by up to 25% in many applications while delivering smoother finishes.

What are common signs of insert failure?

Chipping, premature wear, edge fracture, and degraded surface finish are all signs your insert is failing—replace promptly to avoid toolholder damage or scrapped workpieces.

How can I find detailed technical information on widia grades?

Because Widia does not always publish comprehensive grade charts online, contact your authorized distributor or Widia rep for up-to-date technical datasheets.

Is there a way to save on bulk Widia insert purchases?

Some distributors offer volume discounts or on-contract pricing for repeat users, so always ask about scaled pricing or bundled deals.

—